Introduction

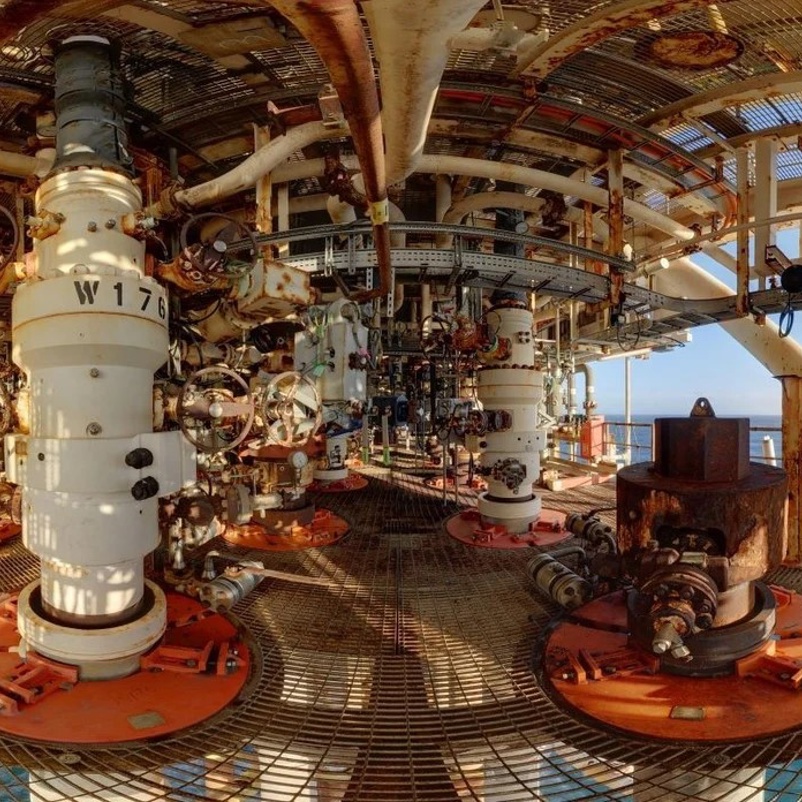

Asset visualization plays a pivotal role in revolutionizing the maintenance and planning processes in the oil and gas industry. By leveraging Digital Twins (DTs), we can create virtual representations of real-world assets and processes, synchronized in real-time, to simulate 'what-if' scenarios and predict future outcomes accurately.

Understanding Digital Twins

A Digital Twin (DT) can be defined in a multitude of ways, ranging from a tool for simulating 'what-if' scenarios to a digital representation of a physical entity. However, the Digital Twin Consortium's 2022 definition provides the most comprehensive understanding. According to them, a DT is “a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity.” In the context of the Oil and Gas (O&G) industry, this translates to an integrated, data-driven representation of assets that can predict future outcomes.

Many products available in the O&G market offer elements of ‘digital models,’ ‘digital shadows,’ and ‘digital twins.’ However, they often fall short of providing a comprehensive solution. This shortfall isn't due to technological constraints but rather the industry's reluctance to fully commit to a single solution or define its target audience.

'Digital models' are limited by their manual data exchange process, resulting in a lack of real-time connection with the asset. On the other hand, 'digital shadows' offer partial automation but lack complete integration with existing systems.

Challenges in Industry Adoption

The O&G industry's cyclical nature further complicates the adoption of DTs. During lean times, cost-saving measures take precedence, limiting investment in new systems. Conversely, during boom periods, the focus shifts to maximizing production stability. This short-term thinking hinders the adoption of a holistic lifecycle approach to assets, which would promote long-term optimization strategies.

Addressing Industry Commitment and Challenges

As a result, many companies struggle to transition from a digital model to a digital shadow or digital twin. Internal factors such as the fear of vendor lock-in, the desire for an in-house solution, resistance to change, and inertia commonly hinder this progression.

Erosion of as-built data over time

In the dynamic landscape of the Oil & Gas (O&G) industry, the importance of accurate as-built data for safe and reliable operations cannot be overstated. Changes to an asset throughout its lifecycle, coupled with the reliance on document-centric systems that are often poorly maintained, result in a disconnect between the as-designed, as-built, and as-operated representations of the asset. This discrepancy, known as data erosion, can undermine the integrity of your asset management data.

Fortunately, the advent of 'evergreen' technology presents a solution. The ability to continually refresh an asset's digital representation over time ensures that the ground-truth remains updated, providing a robust foundation for your data management efforts.

Without this evergreening capability, common issues such as inaccuracies or unavailability of as-built information, inability to view or validate documents without the original authoring tools, or integrate engineering data, can arise. These problems are amplified when applied across different types of data like photogrammetry, laser scans, Piping and Instrumentation Diagrams (P&IDs), electrical schematics, mechanical/structural data, and engineering models.

Quantifying the Value of Digital Twin Adoption

Historically, companies have faced challenges in quantifying the value associated with advancing from a data model of an asset to a digital shadow or beyond. The inherent cost savings and production enhancements may not be immediately apparent. For instance, it's challenging to calculate the number of trips saved because teams of planners, designers, and engineers were able to work remotely during the planning cycle leading up to a Turnaround (TAR). Similarly, quantifying the impact of reduced travel in terms of decarbonization and cost savings is not straightforward.

However, the consequences of data erosion and mistrust in the available asset data are easier to measure retrospectively. Increased travel due to these issues results in escalated expenses that can significantly impact your bottom line.

Maximizing Up-time

Unplanned or scheduled downtime in asset-intensive industries like O&G directly affects costs and production. While some downtime for TARs and maintenance is unavoidable, the goal remains to optimize cost, time, and resource application while reducing risk. Poor data collection management exacerbates these challenges, leading to hidden or hard-to-quantify project risks.

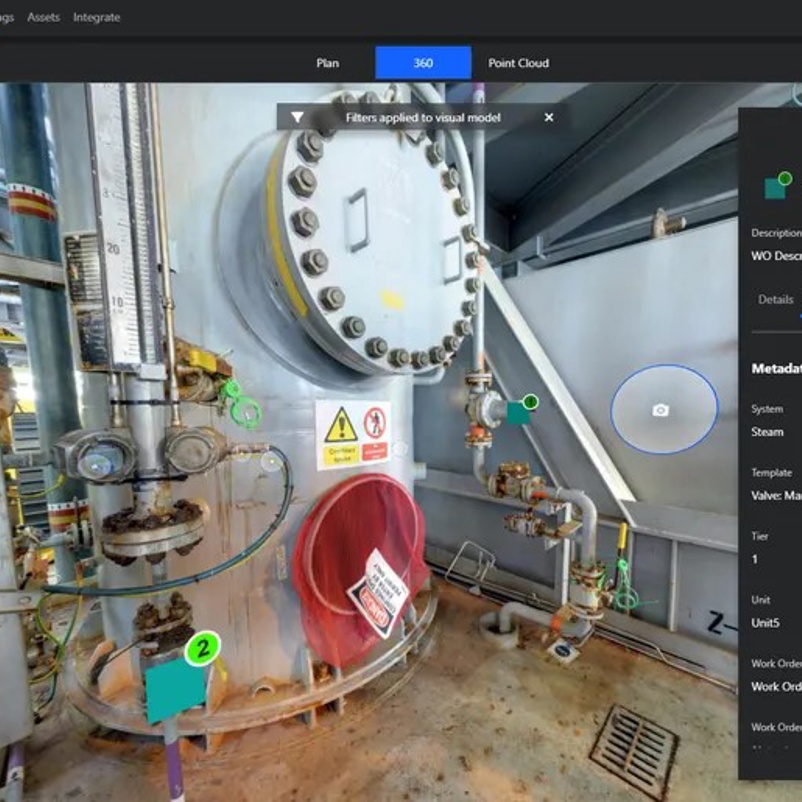

Planning for routine activities like inspections or TARs becomes problematic when the ground-truth doesn't reflect in the documents and drawings being used. In a non-digital world, updating these requires multiple site visits and expensive redrafting. However, in a digital world, a single visit is typically sufficient to refresh the digital twin, enabling most requirements to be met in the office.

In emergency situations, inaccuracies in documentation and lack of ground-truth can pose significant safety risks. For example, if the egress route to lifeboats is blocked due to unrecorded construction or equipment, the existing response plans become obsolete and dangerous.

For activities ranging from routine to emergency, access to accurate information is crucial. The better the data, the more valid the original work plan, resulting in minimized alterations to work packs and reduced impact of minor changes on the profit/loss statement. Moreover, bringing production back online earlier than anticipated can offset the impact of these minor changes.

Cost Savings

The cost-saving advantages of digitalization and digital twins in the oil and gas industry are significant and well-documented. In a presentation by the Abu Dhabi National Oil Company (ADNOC) at the Abu Dhabi International Petroleum Exhibition and Conference (ADIPEC) in November 2022, the company outlined the notable Return on Investment (ROI) from implementing digital twin technology, also referred to as a 'reality twin.'

These ROI benefits included an impressive 80% reduction in site visits by both contractors and NOC personnel, saving 2 to 4 weeks per project, enhancing Health, Safety, and Environment (HSE) and induction training, improving work preparation, risk assessment, and emergency response, among other gains.

While ADNOC did not provide specific dollar figures, the savings from reduced travel alone, given the scale of operations, personnel involved, and number of assets, could easily amount to millions of dollars. The additional intangible benefits, such as reporting decarbonization efforts through remote training, reduced contractor site visits, and minimizing mobilization costs by 45-60 days per project, contribute substantially to Environmental, Social, and Governance (ESG) initiatives.

The value of a well-maintained digital representation of an asset lies in its integration with other systems. This integration drastically reduces search time, a significant challenge in a non-digital world where information retrieval across multiple disconnected systems can be a time-consuming task. In the digital realm, integrating systems like SAP and Maximo, employing optical recognition scanning for drawings, diagrams, and schematics, and visualizing the ground-truth in the digital twin streamline this process. This level of integration could potentially reduce search time by over 90%.

Decision Support and Asset Performance

As computational power has grown exponentially over the last decade, the discussion around decision support systems and predictive analytics, which require high computational capabilities, has intensified. Asset performance management, as defined by Gartner, includes data capture, integration, visualization, and analytics aimed explicitly at improving the reliability and availability of physical assets.

To make informed decisions regarding Capital Expenditure (CAPEX) and Operational Expenditure (OPEX), quick and meaningful access to asset information is crucial. Visualizing asset performance within the context of that asset's lifecycle from multiple perspectives, such as engineering, Operations & Maintenance (O&M), finance, and senior leadership, is also essential.

Consider the impact on ROI using search time as a basis: a mere 5%-time savings in an organization with 1000 active users working 200 days a year equates to 10,000 worker hours. That's equivalent to having an additional 50 skilled workers at no extra cost. By reducing the time spent by skilled employees on tedious searches, decision-making improves, leading to better asset health and a proactive stance based on predictive outcomes.

OPEX Reduction

The integration of visual asset management with digital twin technologies marks a significant stride in the reduction of Operational Expenditure (OPEX). When combined with data science, this approach forms a comprehensive analytical package that drives asset management decisions and enhances Key Performance Indicator (KPI) tracking.

A unified platform can provide critical insights into cost-saving opportunities versus element criticality. This allows for better prioritization of workloads and empowers data-driven decision-making, which is crucial for optimizing operational efficiency.

Cost savings often stem from high technical quality, which in turn is a product of good quality data. Therefore, data collection should be a well-planned process, focusing on collecting information that adds the most value to the decision-making process.

For instance, the selection of data streams for capture should be evaluated based on their direct relevance to various parameters. These might include KPIs influencing management decisions, budgetary considerations affecting OPEX decisions, or emergency response measures driving Health, Safety, and Environmental (HSE) programs.

Collecting data for the sake of having data is neither efficient nor beneficial. Instead, the collected data should serve a purpose, enabling organizations to meet targets and deliver optimal outcomes for the asset and its owner. Therefore, the process of collection management is an ongoing refinement of data collection strategies, tailored to what the organization aims to understand about its asset's behaviour.

Summarily, the use of asset visualization tools powered by digital twin technology is not only invaluable to personnel working on these assets but also significantly enhances workflow efficiency. This, in turn, improves business performance for Oil & Gas asset owners and delivers superior returns to stakeholders.

By embracing asset visualization and leveraging digital twins, the oil and gas industry can enhance efficiency, reduce costs, and achieve better returns for stakeholders. The transformative capabilities of digital twins, when combined with advanced analytics, decision support systems, and data integration, provide a pathway towards a proactive, well-informed, and sustainable future for asset management in the Oil and Gas Industry.

Read James Fisher and Sons plc's latest Annual Report

Read James Fisher and Sons plc's latest Annual Report