The Challenge:

Traditional inspection workflows create delays and backlogs:

• Inspection teams deploy onsite and produce manual reports with photos.

• Reports are sent to the asset integrity team for review and analysis.

• Integrity teams highlight anomalies, assess degradation, assign risk categories, and plan repairs.

By the time decisions are made, teams are asking:

• When was this inspection carried out?

• Is the report still up to date?

The result: delayed feedback, unresolved anomalies, and increased maintenance risk

The Solution

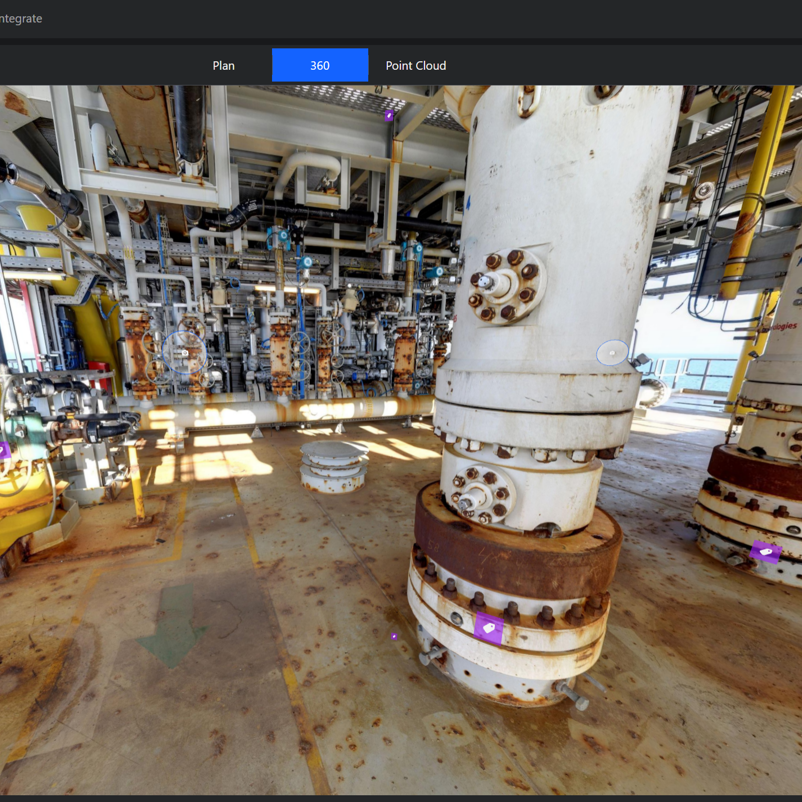

R2S transforms how asset integrity teams manage inspections by combining:

• Real-world imagery

• Data integration (CMMS, ERP, registers)

• Remote visualisation

into a single virtual environment for effective collaboration, monitoring, and planning.

This enables asset integrity teams to see, tag, and act on inspection data in a shared workspace.

With R2S, asset integrity teams can:

• Tag anomalies at exact XYZ coordinates in the asset model

• Apply colour codes to classify severity

• Link tagged equipment to maintenance records, spare parts databases, and documents via direct

plug-ins

• Gain a bird’s-eye view of asset health, anomalies, and work orders

Key Benefits

• Remotely visualise anomalies → better prioritisation of maintenance campaigns

• Remotely monitor inspection tasks → no need for constant site visits

• Combine RBI + R2S → predictive corrosion management

• Enhance productivity → plan effectively before mobilising resources

• Faster decisions → office and field teams collaborate in one shared environment

• Cost savings → cut non-essential site visit

• Time savings → eliminate wasted hours searching for information

• Future-proof → sustain digitalised asset records with AIS self-capture kits

Read James Fisher and Sons plc's latest Annual Report

Read James Fisher and Sons plc's latest Annual Report